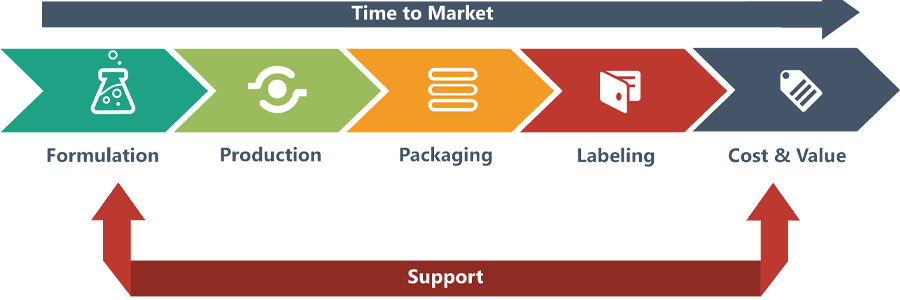

This is part of our Ultimate Guide to Private Label Dietary Supplements, a complete overview of the key advantages of utilizing a private label program, the differences between private label and contract manufacturing, the biggest risks new brands might face, and the top 10 factors you should consider when choosing your private label supplement manufacturer.

A private label dietary supplement program should exist to provide quality, variety, value, and speed to market to a brand. It should also provide convenience and peace of mind to the brand’s owner.

Throughout the entire process of building a premium private label program, decisions must be made along the way that will meet the needs of many, but still stand apart from the competition. Special measures need to be taken in order to include the most in-demand ingredients, with the most safety and efficacy data, in a product range that offers variety and provides value to the brand.

Here we take an inside look at the ins-and-outs of each stage of the private label process and what an optimized private label program does to provide these important benefits.

Formulation

Using Safe, Effective, Symbiotic Ingredients to Create Successful Products

As we discussed in a previous blog post, “How to Manage the 3 Biggest Risks of Offering Private Label Supplements,” this is an industry with thousands of ingredients to choose from. Some are only safe at certain doses, or if a particular part of their source is used (like the root, or the stem,) and some should not be combined due to their effect on each other. Many times, the ingredients are not being properly included in order to make the label claims they carry, which could pose a risk if the product is ever pulled for testing and it doesn’t contain what it is supposed to. Knowing which ingredients are safe, effective, and work well together in a formulation requires knowledge and experience.

Production

Saving Valuable Time to Launch Products More Quickly

The most exciting part of launching a new brand or a new product is the moment it becomes available for purchase. It takes a lot of time to plan out the details of what a brand will be. (For example; Who is the target consumer? Do the products need to be 100% vegan? Etc.) Once all of those decisions have been made, the goal is to get to market as soon as possible.

Avoiding the process of creating a custom formulation is guaranteed to save a lot of valuable time. This avoids the necessary steps of identifying the formulation’s ingredients, sourcing them, testing them for quality and safety, refining their taste and consistency, etc. Beyond that formulation process, however, there is also the time needed to manufacture the finished product.

Placing orders that can be pulled from available inventory is certainly the quickest way to get a product to market. Often the turn-around time for orders like these is just a few days. Even in the case with larger orders, if there isn’t enough inventory to fill the order immediately, the desired amount can be added into a production run that has already been scheduled. Planning for larger private label orders this way can shave months off of the production time.

This is why utilizing successful, on-trend, pre-certified private label supplements can be a huge time saver.

Packaging

Utilizing Smart Packaging Options

In order to effectively meet the needs of thousands of clients, the packaging for private label products need to be practical. It should be something that can easily fit into most brand images, perform well on the machines that will be employed to fill product into bottles or packages, and be durable enough to stand up to packing up and shipping out at least twice – once from the manufacturing facility to the client, and at least a second time from the client to their customer… sometimes there is even a fulfillment center, practitioner’s office, or another stop along the way.

Specific rooms within the manufacturing facility are dedicated to running powders, tablets, capsules, etc. through sophisticated machinery and into various containers, based on the size and volume of each container. Often a tamper-evident liner will top off the bottle, then they are then sealed with a cap, and often a plastic neckband (an additional tamper-evident seal). All of the machinery involved in these processes need to be sterilized both before and after each product batch is run, therefore this is generally done in large quantities to make it cost-effective.

If given the option, it is likely that 10 different brands would choose at least 8 different packaging types as a first choice, which would make it impossible to provide these products at low volumes and/or reasonable prices. Therefore, private label products need to utilize smart packaging options that will make sense in a multitude of situations.

Labeling

Providing FDA Compliant Labels with Low Fees

One of the biggest benefits of a private label program is the ability to order in fairly low quantities. The manufacturer would not maintain inventory in very large amounts for a client who is only ordering in small amounts. Therefore, the brand’s labels are usually printed out in the needed quantity and applied to the products as they are ordered. Often the labels are applied by hand, as the order isn’t large enough to warrant the set-up of a labeling machine. This is referred to as a labeling service and provides value to the brand in minimizing label inventory fees and such.

Having the manufacturer provide the labels relieves the brand of enormous responsibility. In the United States, the Food and Drug Administration (FDA) regulates the labels of all dietary supplements. In one of our previous blog posts, “How to Manage the 3 Biggest Risks of Offering Private Label Supplements,” we explain that dietary supplement labeling is subject to a unique set of rules and regulations. Non-compliant labels can come with some pretty serious consequences – such as large fines, product recalls, or even the end of the brand.

When a private label manufacturer supplies the labels for the products, they are responsible for the labels being compliant with FDA requirements. This should provide the brand with a sense of comfort, and confidence in knowing that their manufacturing partner is invested in the safety and success of the brand.

Cost and Value

Using Experience, Relationships, and Market Knowledge to Provide Value

In order to provide value to the client, the manufacturer needs to be an expert at managing the cost and quality of the formula.

Keeping the cost down while achieving the highest possible quality requires experience. Past work with different ingredients, suppliers, packaging components, or product formulations will provide the manufacturer with a history of wins and losses to have learned from. Their years of experience have provided trusted supplier relationships. They have access to the newest and highest quality of ingredients and packaging components, and their reliable, high-volume orders help provide lower costs for them; savings which can be passed on to the client.

In addition to managing the cost of the various components of the product – ingredient sourcing, product formulation, product packaging, and FDA-complaint labels, applied per-order – the manufacturer has to ensure that the product formulation will be competitive in the market. Therefore, the manufacturer has to know the market well and calculate accurate product costs versus retail prices, in order to make sure they are providing a product of value to their clients.

Support

Providing Expert Guidance from Product Selection to Sales Promotions

A seldom-discussed benefit of working with an experienced private label supplement manufacturer is the level of support the brand should be getting. Throughout the process, there should be assistance, if desired, with decisions such as which products to offer, finding the selling points for a private brand with national brands, when to run a sales promotion and on what products, or providing a track record of success with a product. With a brand-new customized product, this type of information – competitive selling points or historical knowledge, for example – will not be available, and is often where costly mistakes are made. When working with established, pre-certified private label supplements, there should be a knowledgeable point of contact and/or sales rep to provide guidance to the brand, right from the beginning.

Summary

When private label brands first started out, they had a slightly different perceived value than they do today. They may commonly have been considered as being generic – not unique at all, or cheap – of lower quality than a name brand product.

Over the past decade, however, many private label supplements have experienced significant sales growth because of the value they offer. Consumers have grown to appreciate the passion of these small brands, the quality of their products, the transparency of the brand, and the product guarantee. They also recognize the value of purchasing a product with all of the positive attributes a larger brand might carry at a 20% to 30% lower price point, while feeling more satisfied in making the purchase from a specific, local, or smaller company.

These are some specific things to look for in an on-trend, pre-certified private label supplement manufacturing partner in order to obtain products of high quality and value. If it feels too much like slapping a basic label on a basic product, it’s probably not the right program.