This is part of our Ultimate Guide to Private Label Probiotics, a complete overview of the benefits of probiotic supplementation for consumers, some of the different strains and their specific uses, the process of responsibly manufacturing a probiotic product, and what to look for when choosing a probiotic manufacturer.

The dietary supplement category is both crowded and competitive, and it can be very confusing for consumers to recognize the quality of your brand. This is especially true for probiotic supplements due to the many challenges involved in manufacturing with these live organisms, and the different methods of labeling their active culture counts.

Consumers have become increasingly aware of the many health benefits probiotics can offer beyond gut health, and they are looking for more product options around potency, strains, gender, age, and other specific health conditions. They want advanced blends, targeted formulas, and shelf-stable products that don’t require refrigeration. They also want transparency and traceability, so they can be confident that the product they are choosing will provide the health benefits they are seeking.

The following are the most important criteria to look for when selecting a private label or contract manufacturing partner for your probiotic supplement.

Are CFUs Counted Through Expiration?

A commonly utilized deciding factor in selecting a probiotic product is the number of CFUs (Colony-Forming Units) it contains. CFUs are the groups of live microorganisms delivered in each serving of the probiotic. There are many challenges in keeping these delicate cultures alive until they are eventually consumed. The transportation or storage of probiotics in an unsuitable climate, for example, can easily kill them. Therefore, learning how many CFUs were present “at the time of manufacture” is not a reliable measure of what is still viable at the time of consumption.

ConsumerLab.com recently tested 19 probiotic finished products labeled as “at time of manufacture” only to find that five of them contained only 16 percent to 56 percent of the listed amounts of organisms.

Look for labels that state the CFU count “through expiration” to ensure this amount is provided in every dose until the product meets its expiration date.

Are The Right Strains In The Blend?

ARE TARGETED FORMULAS USING CAREFULLY SELECTED STRAINS?

A probiotic product offering advanced blends may use several different probiotic strains in order to target one specific health benefit. The manufacturer will be careful to select strains that are hardy and that have supportive research to provide the desired benefits and will ensure that their finished formulation will protect them as they make their way into the gut.

Targeting Specific Health Conditions.

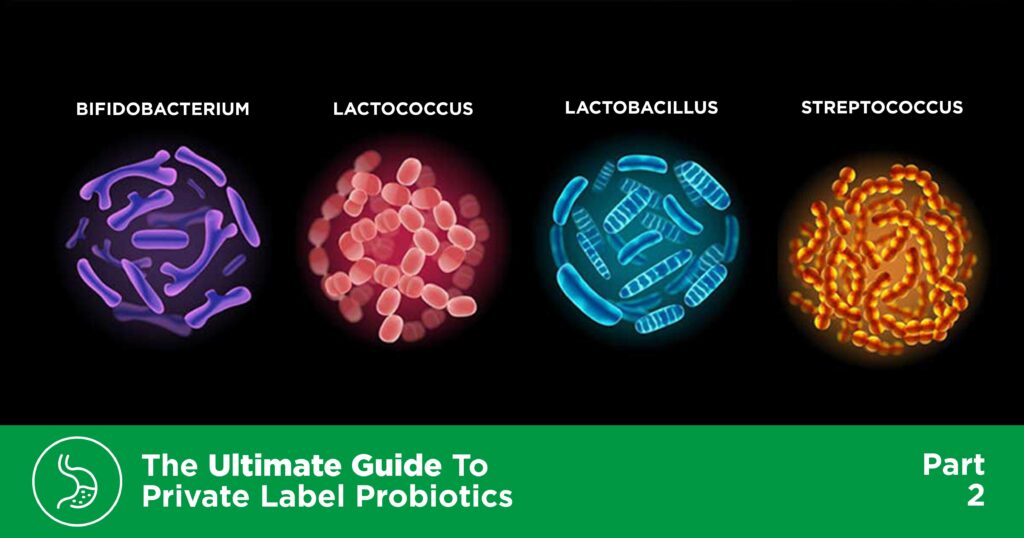

Probiotic supplements can be formulated to target specific health conditions by including specially selected bacterial strains. For example, although Lactobacillus and Bifidobacterium are the most commonly used strains, there are several other strains that can provide more diverse and specific health benefits. For example, the lactobacillus helveticus and bifidobacterium longum strains have been shown to help reduce symptoms of anxiety and depression. There’s even a relatively new name for probiotics that function in this way: “Psychobiotics”. These are a specific group of probiotics that affect the central nervous system and behaviors mediated by the “gut-brain-axis”.

Selecting these strains can provide a potent formulation to be used when trying to address a specific health issue. Past and ongoing clinical research helps to identify which probiotic strains offer the greatest health benefits, either for overall health or for targeting specific conditions.

Providing More Probiotic Diversity.

In addition to condition-specific bacterial strains, supplements can also be formulated with a focus on using multiple strains in order to deliver more overall health benefits. Based on a number of studies, multi-strain probiotics appear to show great efficacy and beneficial effects on improving overall health.

Multi-strain probiotics can be used to target a wide range of health issues at once. Combining several different strains may be helpful with conditions such as indigestion, irritable bowel syndrome, gut wellness, diarrhea, immune support, respiratory infections, gut microbiota modulation, digestive support, regularity, irritated bowels, gas & bloating, autism, depression, anxiety, and healthy mood support. The option to take just one product for such a broad spectrum of health benefits is both convenient and affordable.

ARE ADVANCED BLENDS INCLUDING ADDED ACTIVE NUTRIENTS?

A probiotic product offering targeted formulas may include additional active ingredients that have been shown to provide a benefit for a specified health condition. Just as the probiotic strains mentioned above have been shown to be helpful with mood support, there are specific herbs and other nutrients that can offer this benefit. For example, inositol has been shown to be as helpful as some prescription medications in reducing the intensity and frequency of panic attacks with minimal side effects. Theanine has been shown to elevate levels of GABA, serotonin, and dopamine in the brain. These chemicals kare nown as neurotransmitters, and they can help to regulate emotions, mood, concentration and more. Increasing levels of these calming brain chemicals has been shown to promote relaxation and significantly improve stress-related symptoms.

Advanced blends and targeted formulas can be very beneficial for those with specific health concerns, and consumer demand for these products is high. Private label probiotic offerings should include products that incorporate proven strains and other added nutrients to provide highly effective products that are optimized for potency and stability.

Are Prebiotics Included?

Prebiotics are the healthy food that probiotics need in order to survive and thrive. Foods in the diet that are high in fiber provide various health benefits. When this fiber is consumed, it’s fermented in the large intestine by the bacteria that live there. This fermentation process creates the prebiotics. In addition to providing a food source for probiotics, the presence of these prebiotics helps to strengthen and increase the number of good bacteria, and also to suppress the growth of bad bacteria, which creates an optimal environment for good digestive health.

Types of Prebiotics

For the most part, the prebiotics used in probiotic supplements are either oligosaccharides or inulin.

Fructo-Oligosaccharides (FOS) and Galacto-Oligosaccharides (GOS) are resistant to the human digestive enzymes that work on all other carbohydrates, so they are able to pass through the upper GI system without being digested. They then get fermented in the lower colon and produce short-chain fatty acids that feed the beneficial bacteria that live there. Both of these oligosaccharides have been shown to help support the immune system and cleanse the body of potentially harmful bacteria.

Inulin is a type of soluble fiber that is found in many plants and is also added into many dietary supplements as a food source for probiotics. Inulin has also been shown to help support the immune system and can help to slow the digestion process, which can facilitate better absorption of nutrients from food and prevent spikes in blood sugar from carbohydrates.

The best probiotic formulations will include at least one type of prebiotic, as it is important to provide a food source for the probiotics to consume once they have made their way into the gut.

Were Raw Materials Stored and Transported Properly?

Because they are living organisms, probiotics have unique handling needs at every stage of the manufacturing process. Environmental conditions, particularly heat, humidity, and oxygen are key considerations for an experienced manufacturer looking to create a viable probiotic supplement.

The probiotic raw materials must be shipped and delivered to the manufacturer under appropriate temperature and humidity conditions. This will generally require the use of dry ice or a refrigerated truck. Upon arrival, the material will need to be refrigerated (or frozen) immediately and placed “on hold” for a quality assurance check.

Once the manufacturer has confirmed that the organisms have survived their trip to the facility, it is important to handle them carefully. Proper temperature and humidity levels need to be maintained throughout all stages of production. All steps in the manufacturing process should be carefully scheduled when working with probiotics, taking into account each point at which the probiotics may be left out or encounter any temperature fluctuations.

An experienced private label probiotic manufacturer will have precise knowledge of each of these steps and will have equipment specifically for controlling temperature and humidity throughout the process.

Was Formulation and Manufacturing Handled with Care?

Manufacturing with probiotics can be challenging due to the delicacy of the live organisms. Using a manufacturing facility with Good Manufacturing Practices (GMP) certification by a third party attests they have stringent processes, procedures, and documentation in place. GMP certification also validates that products have the identity, composition, potency, and purity declared on the product label. During the process of formulation, R&D determines which ingredients should be included in order to achieve the desired health benefit. The product will be formulated using an effective starting dosage (measured in CFUs) to ensure viability through expiration date. Depending upon the type of finished product they will become, appropriate protocols will be followed to prevent conditions that may negatively impact the stability of the finished product.

During the manufacturing process, the high microbial counts of the probiotic raw materials could present a risk of contaminating the air, manufacturing rooms, surfaces, equipment or other products within the area, so appropriate moisture control, cleaning, and sanitation protocols must be adhered to while they are being processed. Additionally, appropriate climate-controlled conditions need to be maintained at all times to ensure the vitality and health of the organisms.

Is Quality Control and Testing Heavily Involved Throughout?

It is of utmost importance that Quality Control is involved at critical stages of the probiotic manufacturing process. This begins when samples are taken as the product is received and continues through blending, encapsulation, bottling, and shipping. These measures are necessary throughout production to ensure the stability of the product, and to ensure no cross-contamination has occurred.

There are three main types of testing your probiotic manufacturer should employ:

- Real-Time Stability testing is when a sample of the finished product is retained at recommended storage conditions and monitored at specific time points, such as monthly or yearly. Products in storage will change as they age, especially products with live organisms inside them. This real-time data provides an accurate measure of how viable the product will be from the time it was made until its expiration date.

- Accelerated Stability testing is a modified method used to quickly estimate the life span of a product when real-time data is unavailable, such as with a new product. The finished product is subjected to an elevated level of stress, such as controlled changes in temperature or humidity, to mimic similar conditions the product may have experienced over a certain timeframe.

- Third-Party testing is where an impartial expert is enlisted to verify the probiotic finished product contents and identity, to confirm that the product was manufactured in consistent, compliant conditions, and in some cases to ensure the product label is accurate and compliant with regulatory standards.

Once all of the internal and third-party testing and data collection has been completed, the manufacturer will release the finished product to be sold by their private label customers.

Is the Finished Product Shelf-Stable?

Many probiotics are now being manufactured as shelf-stable, which means that they do not have to be refrigerated to remain viable. This is much more convenient for retailers and consumers. Shelf-stable probiotics require specific manufacturing and quality control steps in addition to those required for probiotics requiring refrigeration. The number of days that the product remains stable at appropriate storage conditions is referred to as the “shelf life” of the product.

Stability testing of finished products is necessary to determine the projected lifetime and expiration date. Some manufacturers only perform accelerated stability testing, usually in an effort to get a new product to market as quickly as possible. That is often the reason the CFU count on a product is listed “at time of manufacture”, rather than “through expiration date”. This does not provide clear information to the consumer of how many cells are still viable when they are taking the product a month after it has been manufactured, or six months after that when it is at home with them. This is where real-time stability testing has the advantage, as providing a much more accurate measure of the stability of the finished product.

There are many ways the probiotic manufacturer can achieve this stability. Some use patented probiotic strains that have been manufactured using specially designed processes to preserve and ensure the stability of the organisms, without the need for refrigeration. There are also special capsules that can be used to protect the probiotics in their dormancy.

Summary

At the end of the day, you want to select a probiotic manufacturing partner who can offer you turnkey solutions, technical support, and training to help you successfully bring your products to market. Your manufacturer should have the experience and expertise to create viable, beneficial probiotic products that deliver what they claim to on the label. They should also be able to educate you about exactly what your product does, to support you in product development and sales.

Your customers demand transparency and accountability in their health supplement products. A private probiotics manufacturer should be committed to helping you achieve a formulation that fits the exact performance benefits your customers are seeking.

†These statements have not been evaluated by The Food and Drug Administration. This product is not intended to diagnose, treat, cure or prevent any disease.